Turnstile Mechanism Video:

Turnstile Mechanism Description:

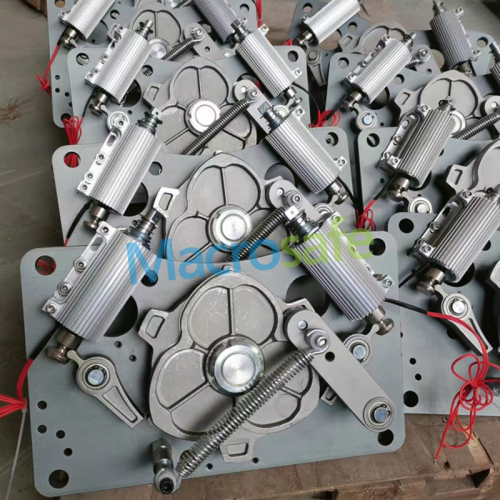

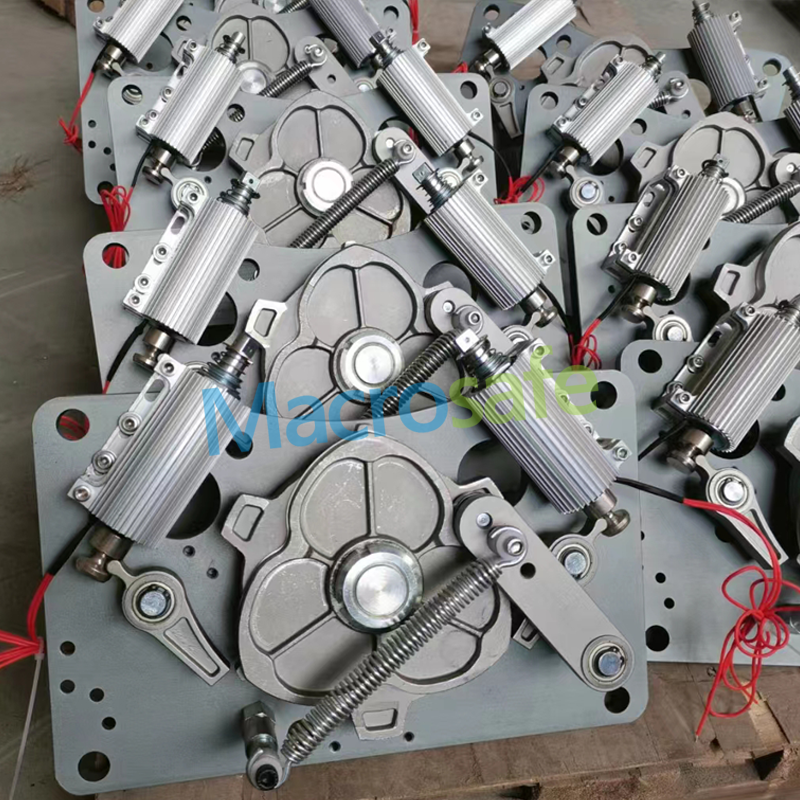

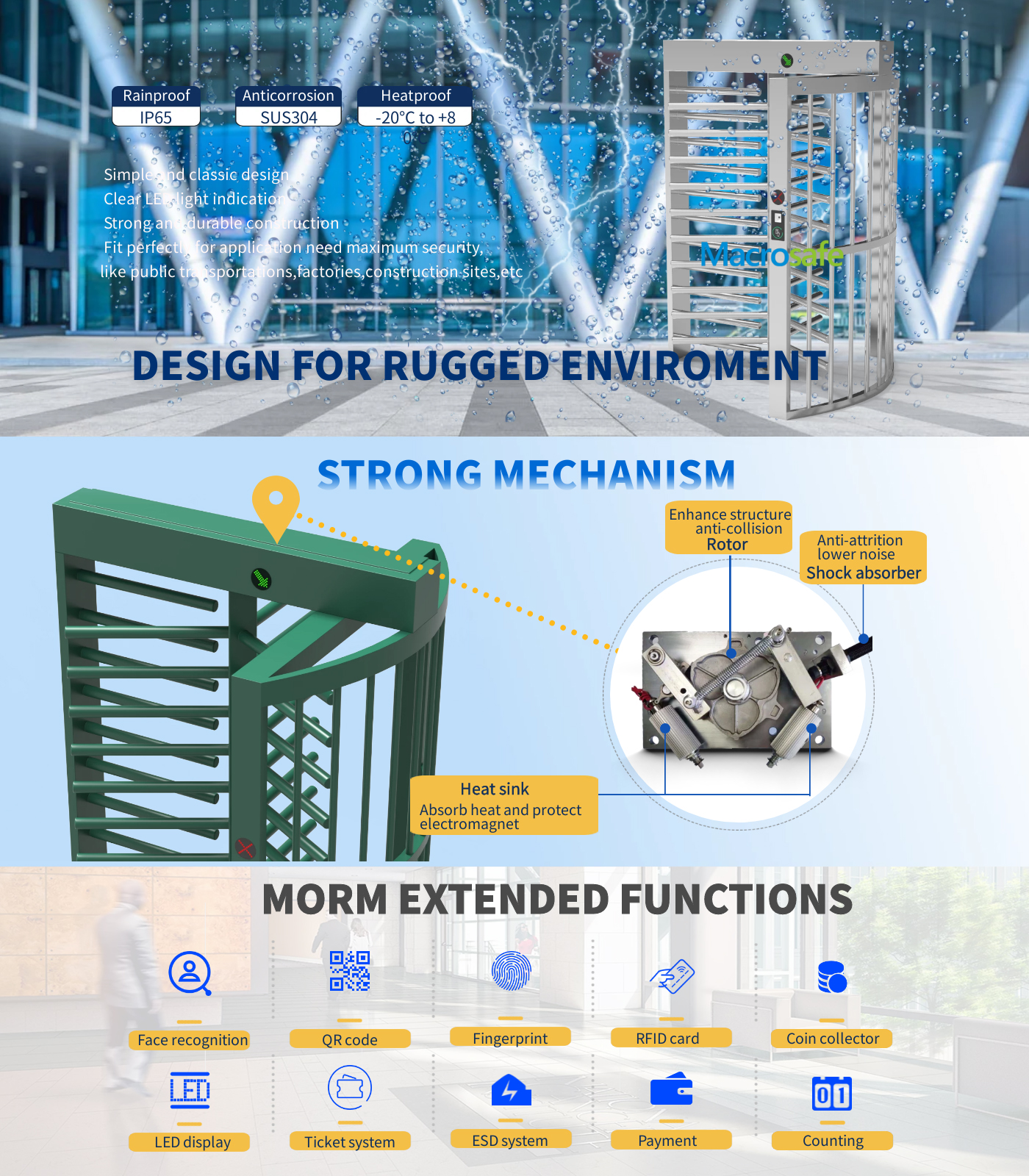

Turnstile mechanism is the heart of turnstile gate, which plays a vital role in ensuring the smooth, stable and quiet operation.

In occasions with high traffic flow, people come in and out very frequently, which tests the wear resistance and impact resistance of the mechanism.

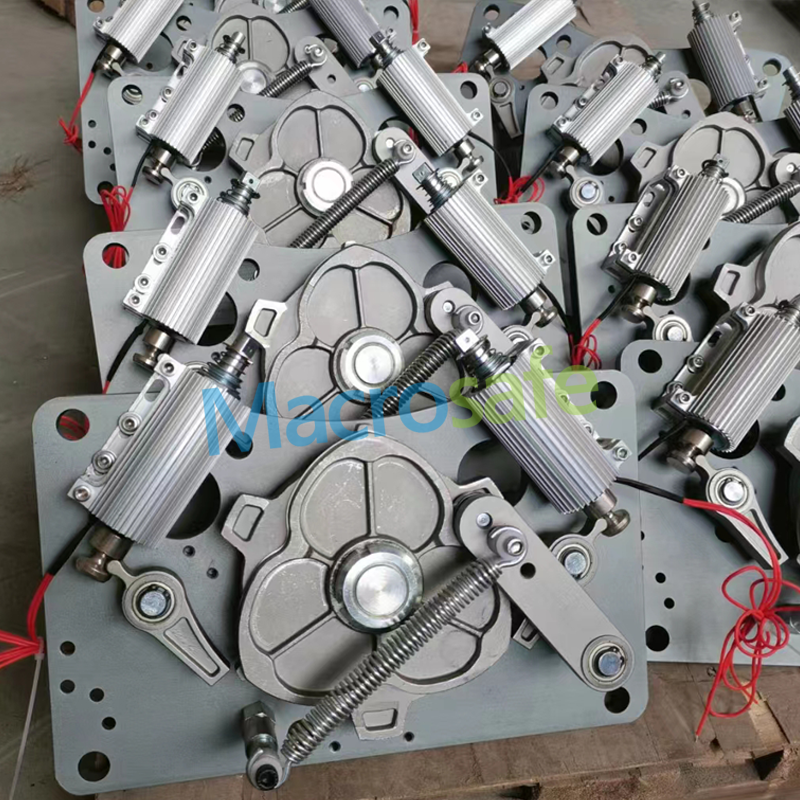

The parts of the mechanism are processed by CNC machine tools, and the precision grade processing accuracy is used to ensure the processing accuracy of the movement parts, so as to ensurehigh performance, stability and long life of the mechanism.

In addition to the stainless steel parts of the turnstile gate mechanism, other anti-oxidation processes such as nickel plating are used to enhance the wear resistance and corrosion resistance of the parts.

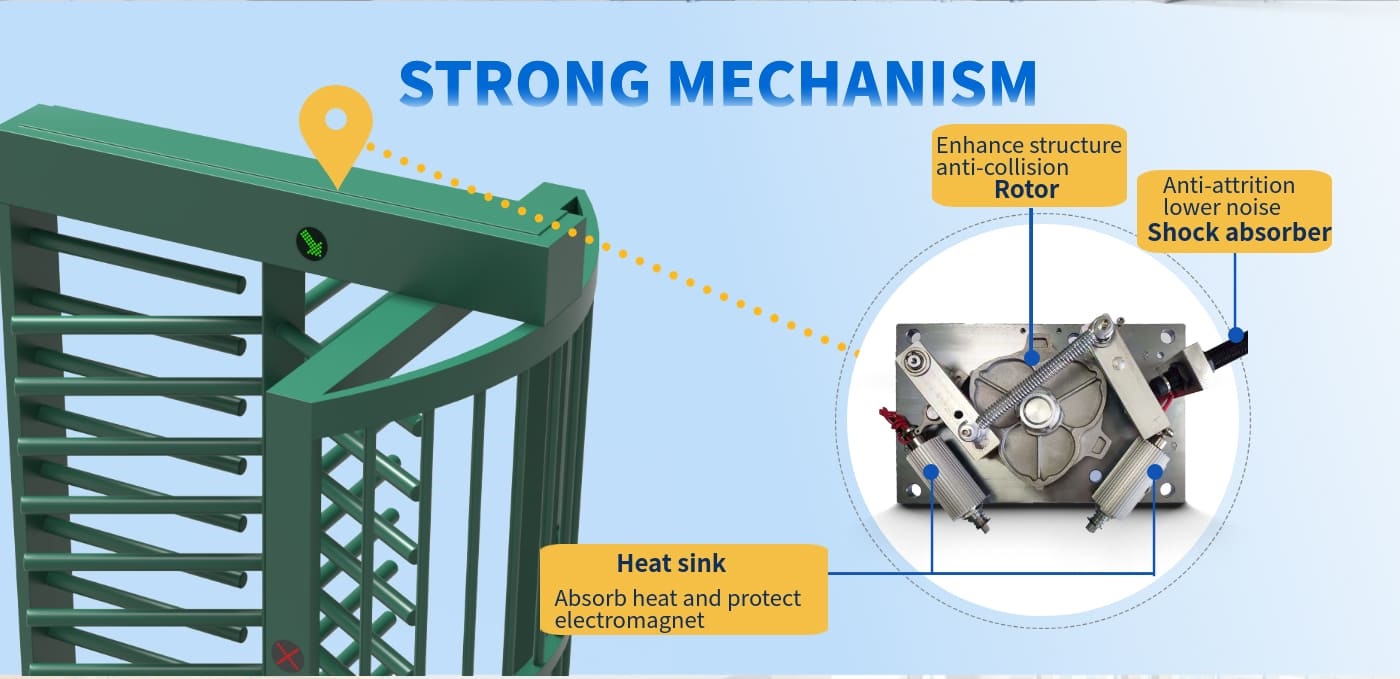

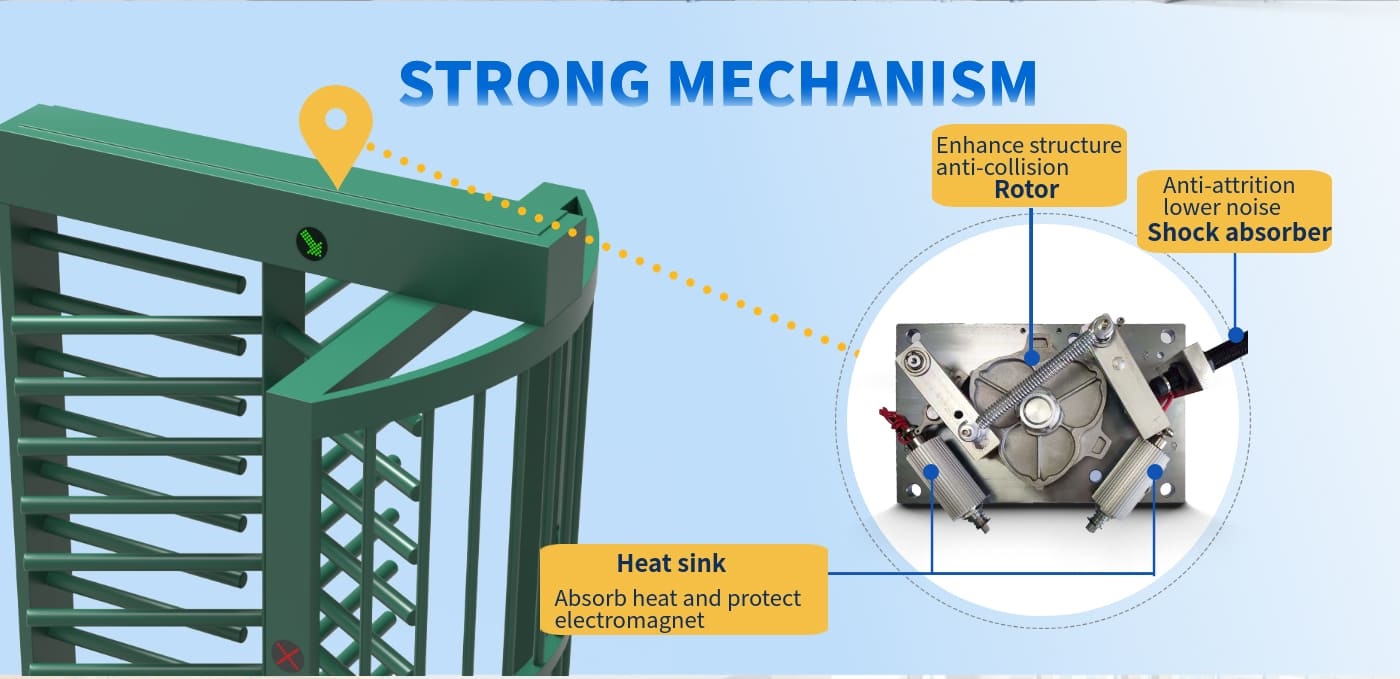

With strong structure, heavy-duty materials, and a unique hydraulic buffer module, Macrosafe's self-developed turnstile mechanism can effectively buffer the impact of obstacles on the movement when rotating, protect the mechanism, and reduce noise during operation.

Contrary to the electromagnet on the tripod turnstile mechanism, the electromagnet of the full height turnstile mechanism is always working until it receives a signal to open the door, and it stops working, allowing passage. Therefore, continuous work for a long time will cause serious heat generation and affect the life of the electromagnet. Macrosafe's unique heat sink can effectively help it dissipate heat and prolong its working life.

How to set up turnstile mechanism via controller?

Turnstile Mechanism Variations:

Turnstile mechanisms include full height turnstile mechanism, tripod turnstile mechanism, swing barrier mechanism, flap barrier gate mechanism and speed gates mechanism.

Full height turnstile mechanism is mainly discussed here. According to the driving method, it is divided into semi-automatic and fully automatic (also called motor-driven). It is divided into 90 degrees and 120 degrees according to the rotation angle. If you want to know more, please contact us directly.

What are the components of full height turnstile mechanism?

The components of a full-height turnstile mechanism include:

A base, a limit sensor, two electromagnets, a hydraulic buffer, a heat sink

What are the components of tripod turnstile mechanism?

The components of a tripod turnstile mechanism include a base, three arms, and a drive motor. The arms are typically attached to a central post, and the motor powers the rotation of the arms.

The arms are linked to one another via rods, which allows them to move in unison when the motor is activated. In addition, the arms are typically locked in place when not in use to prevent unauthorized access.

How to Maintain Full Height Turnstile Mechanism?

As we all know, the engine is the heart of the car, and the car needs to go to the 4S point for maintenance every year. Mechanism, as the heart of the turnstile, also needs regular maintenance. For specific maintenance steps, please refer to the following:

1. Disconnect the switch power supply, open the upper cover of the full-height gate, clean the dust inside, and add appropriate lubricating oil to the transmission gear and wheel groove.

2. Check the various parts of the movement to see if they are loose or fall off, and re-tighten them. Add lubricating oil to the humidity in the solenoid valve to reduce the friction and loss during its movement, so as to prolong the service life.

Check whether the electromagnets and limit switches on the movement are working properly, and if they are damaged, replace the parts in time.

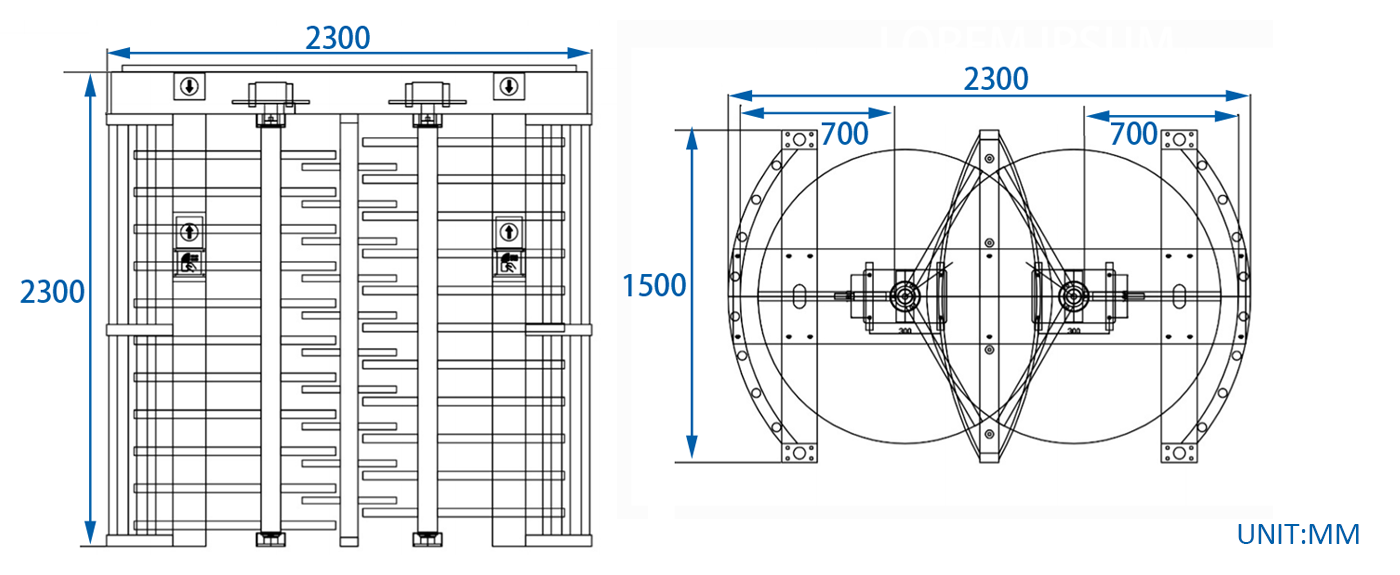

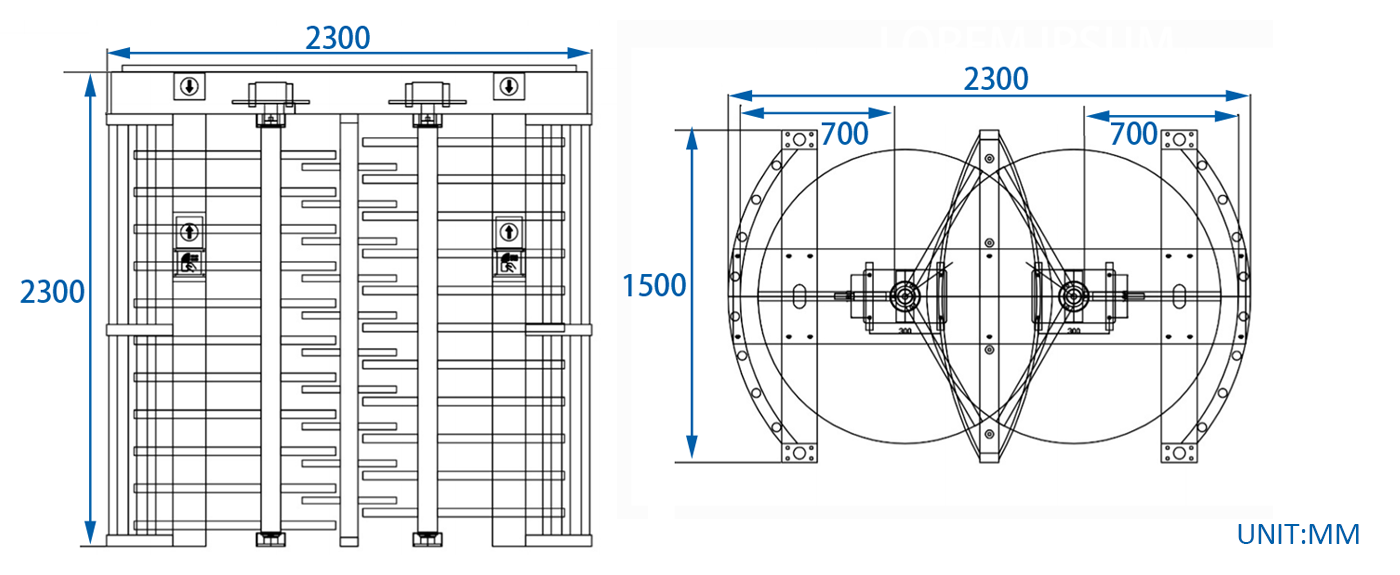

Turnstile Dimension: