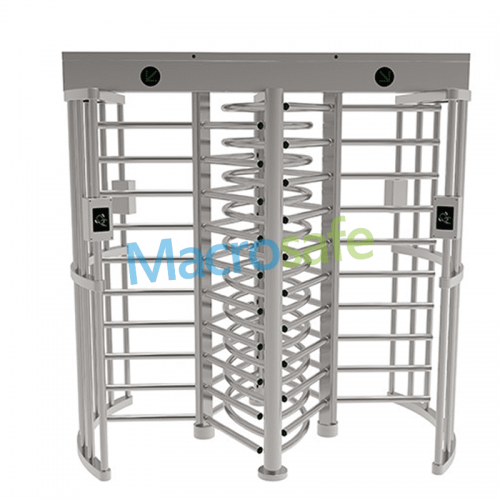

Industrial turnstiles are a type of security gate that is used to allow or restrict access to a work site. They are typically found in industrial settings such as construction sites, factories, warehouses, and production lines.

Industrial turnstiles are an essential component of security systems in industrial areas. Their main purpose is to control the flow of employees and goods through entry and exit points, ensuring that only authorized individuals are granted access.

Industrial turnstiles are designed to be sturdy, reliable, and tamper-proof, making them ideal for use in high-security areas such as construction sites, factories, warehouses, and other industrial facilities.

1. Not level: Make sure the industrial turnstilee is level before installing. An unlevel turnstile can cause problems with the functionality and the aesthetic of the product.

2. Incorrect hardware: Be sure to use the correct hardware when installing a industrial turnstile. The wrong type of hardware can damage the product or cause it to not function properly.

3. Not plumb: The industrial turnstile must be plumb in order to function properly. This can also cause problems later on, so make sure to use a plumb line when installing.

4. Poorly installed base: A poorly installed turnstile base can cause the industrial turnstile to be unstable and unsafe. Be sure to follow the manufacturer’s instructions when installing the base.

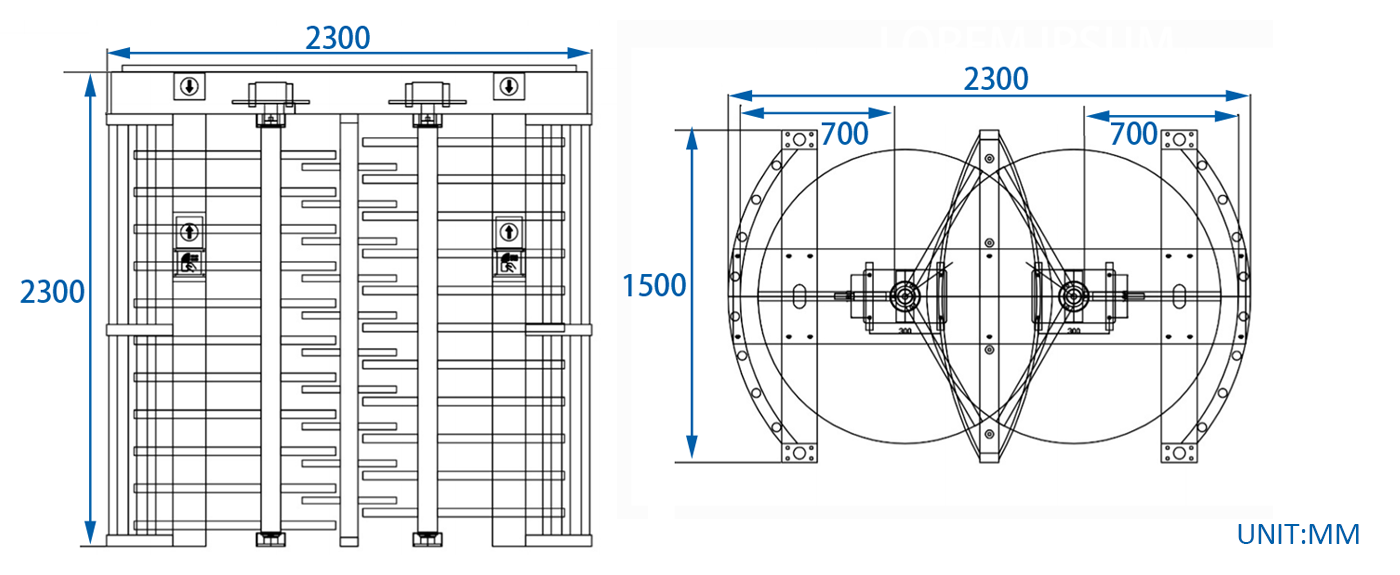

5. Wrong size: another mistake that is often made is using the wrong size turnstile for the installation. This can cause the turnstile to be too small or too large for the space, so make sure to measure the space before purchasing the turnstile.

6. Not following the manufacturer’s instructions: Be sure to follow the manufacturer’s instructions when installing a turnstile. Not following the instructions can void the warranty and can cause the turnstile to not function properly.