What Is Retractable Bollards?

Retractable bollards , also called automatic bollards, telescopic bollards and rising bollards, are a type of traffic barrier that can be manually or automatically retracted into the ground, allowing vehicles to pass through. Manually retractable bollards are operated with a single-key locking mechanism, while automatic bollards use hydraulic or pneumatic technology to control their movement.

Retractable bollards are typically used in locations where vehicle access needs to be restricted, such as pedestrian areas, parking lots, and private driveways.

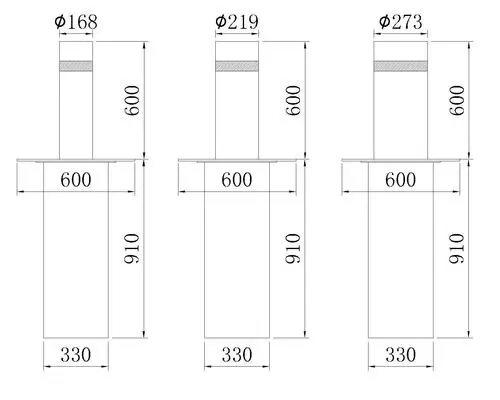

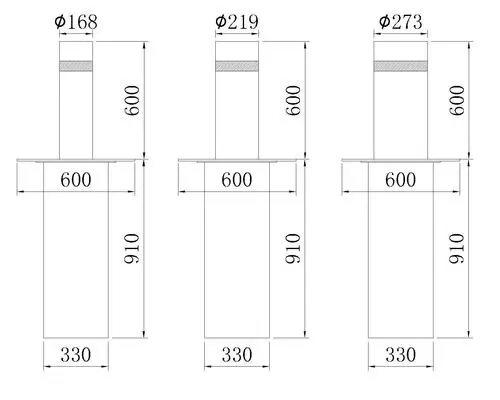

1.1 Size of Hydraulic Bollards

The hydraulic bollards come in different sizes.

The diameters available are 168mm, 219mm, 273mm, and 325mm.

The height (above ground) options include 400mm, 600mm, 800mm, 1000mm, 1200mm, and 1500mm.

As for the thickness, you have choices of 6mm, 8mm, 10mm, 15mm, and 20mm.

1.2 What is the standard retractable bollard distance?

According to industry standards, the general installation distance for retractable bollards is typically between 0.8 to 1.5 meters. The purpose of this installation is to effectively prevent unauthorized vehicle access while allowing pedestrians and electric bikes to pass through without hindrance.

1.3 How strong are retractable bollards?

Macrosafe retractable bollards can withstand impacts from vehicles weighing up to 8 tons and successfully handle vehicles weighing up to 100 tons without any loss in performance. With an IP68 waterproof rating, these bollards can also operate normally even when submerged in water.

4 Main Components of Hydraulic bollards

1. Bollard post: 304 stainless steel seamless steel pipe, with strong load-bearing and impact resistance; high waterproof level. Retractable bollards are buried in designated positions on the driveway or gate, it raises or lowers through remote control (or access control system).

2. Hydraulic transmission station: It is composed of fuel tank, manual oil pump, a full set of hydraulic solenoid valve group, high-power motor, oil pump, oil cylinder, oil gauge, high-pressure hydraulic oil pipe, etc. It is the power source of the whole set of roadblock system, and the device is installed in retractable bollards side, used in conjunction with it.

3. Electric control system: It is composed of PLC control board, leakage switch, non-contact noise and high-life contactor and other precise start-up time settings.

How do Automtaic Bollards Work?

Automatic bollard is a kind of bollard with hydraulic motor as the power unit, including hydraulic integrated rising bollard and hydraulic split rising bollard. Their power units are all hydraulic motors.

The mechanism of automatic hydraulic bollards involves the use of a hydraulic power unit (HPU), a control system including programmable logic controller (PLC), and the bollard shaft.

The mechanism of automatic hydraulic bollards involves the use of a hydraulic power unit (HPU), a control system including programmable logic controller (PLC), and the bollard shaft.

1. Using a remote control (or access control system includes devices, such as card readers, keypads or biometric sensors,) sends a signal to the control system.

2. The control system analyzes and processes through the plc, and controls the relay according to the command to start the contactor and start the motor.

3. After the motor starts, it drives the gear to rotate, and compresses the hydraulic oil into the hydraulic cylinder through the integrated valve. Pushing the hydraulic cylinder to extend and retract, the bollard retracts flush with the ground, allowing authorized vehicles to pass through

4. Once the access is rejected, the PLC sends a signal to the HPU, which then pumps hydraulic oil into the automatic bollard to raise it.

How Much Are Retractable Bollards?

The cost of a retractable bollard will depend on various factors, such as the material, installation, and size. Generally, the price range can vary from $200 to $500 per unit.

It’s essential to note that the cost of these bollards will also vary depending on the features included, such as lighting or a locking mechanism. When considering purchasing retractable bollards, it’s important to also factor in the ongoing maintenance and repair costs to ensure they remain functional over time.

Overall, the cost of retractable bollards can be a significant investment, but it’s an important measure to ensure the safety and security of your property.

Where to Buy Retractable Bollards?

Retractable bollards can be purchased through a variety of sources. Macrosafe is absolutely your first and perfect option. As a professional manufacturer with years of experience,Macrosafe products meet industry standards and are of high quality. Please click the following bollards for more information.

Click here to contact our security experts to discuss your specific needs for retractable bollards. We can provide customized solutions and guidance on selecting the right product for your application.

Types of Bollards

After years of development, bollards have expanded into various styles, and there are three main categories: automatic bollards, semi-automatic (manual) bollards and fixed bollards.

Automatic bollards:

1. Pneumatic bollards: Air is used as the driving medium, and the bollards are driven up and down through an external pneumatic power unit.

Pros: Responsive and fast rising & lowering

Responsive and fast rising & lowering

Cons: Complicated installation and high maintenance costs

Complicated installation and high maintenance costs

2. Hydraulic bollard: Hydraulic oil is used as the driving medium. There are two control methods, that is to drive the bollards up and down through the external hydraulic power unit (the driving part is separated from the bollards) or the built-in hydraulic unit power unit (the driving part is placed in the bollards).

Pros: Excellent waterproof performance, long service life, suitable for harsh environments

Excellent waterproof performance, long service life, suitable for harsh environments

Cons: A little bit Slower rising & lowering than pneumatic

A little bit Slower rising & lowering than pneumatic

3. Electromechanical bollard: the column is driven up and down by the built-in motor of the column.

Pros: Lower cost

Lower cost

Cons: Poor waterproof performance, not suitable for rainy environment

Poor waterproof performance, not suitable for rainy environment

Semi-automatic (manual) bollards

1. Semi-automatic bollard: The ascent process is driven by the built-in power unit of the bollards, and the descent is completed by manpower.

2. Pull-type bollard: The ascent process needs to be lifted by manpower, and the fall depends on the weight of the bollard itself.

3. Removable bollard: The bollard and base are partly designed separately, and can be removed when not needed.

Pros: Lower cost and simple maintenance

Lower cost and simple maintenance

Cons: The rise of bollards depends on manpower

The rise of bollards depends on manpower

Fixed bollards:

1. Fixed bollard: the bollard is directly fixed to the road surface.

The main use occasions and advantages and disadvantages of various types of columns are different, and the type selection should be based on the actual project when using it.

Pros: Lower cost, easy installation

Lower cost, easy installation

Cons: Not flexible, non-retractable

Not flexible, non-retractable

For some high-security applications, such as military bases, prisons, etc., it is necessary to use anti-terrorist bollards. Compared with general civilian-grade bollards, the thickness of the column generally needs to be more than 12mm, while the general civilian-grade bollards are 3-6mm. Beyond that, installation requirements vary.

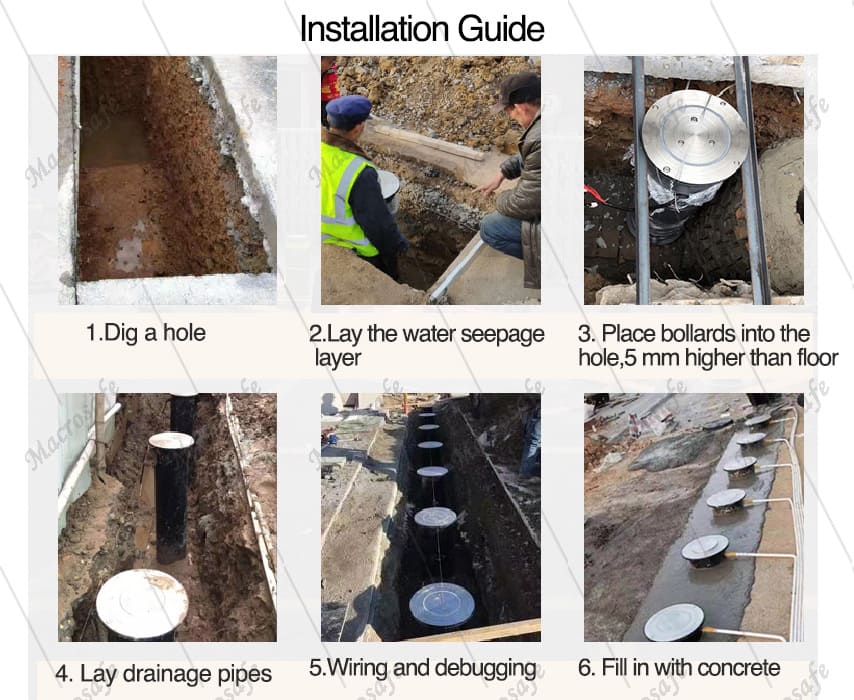

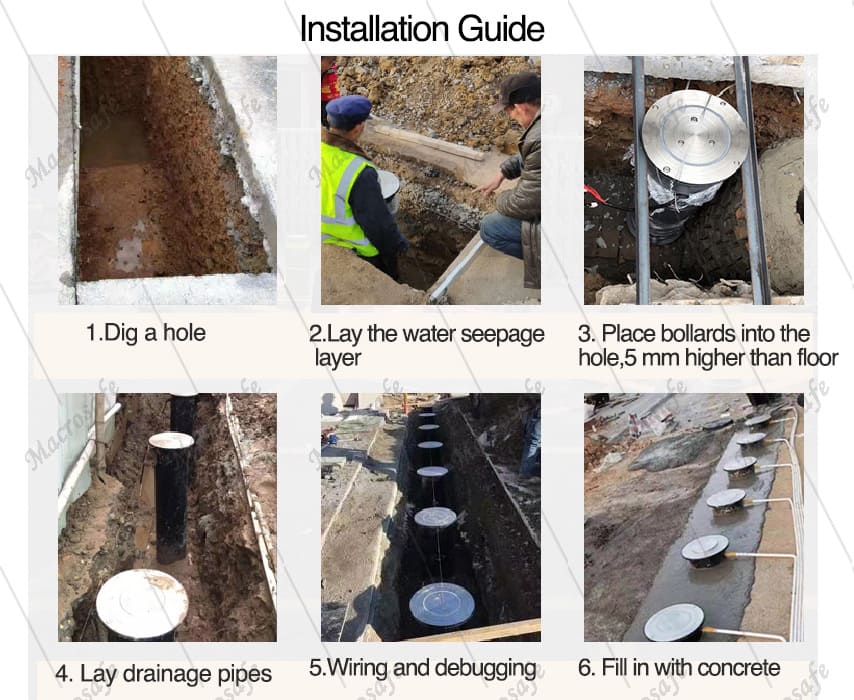

Quick Guide for Hydraulic Bollard Installation

Here's a step-by-step guide on bollard installation:

Here's a step-by-step guide on bollard installation:

1. Digging hole, width 800mm, depth 1300mm

2. Lay the water seepage layer, use sand and small stones to make a water seepage layer with a height of 200-300mm at the bottom of the foundation pit

3. Fixed hydraulic bombards

Fix the hydraulic bollards with angle irons to make them 5mm above the ground.

4. Choose whether to lay drainage pipes according to the region.

5. Wiring debugging after fixing hydraulic bollards.

6. Finally, fill the gap with concrete and wait for it to dry before using it.

7. Make sure to maintain the bollard and its foundation regularly to prevent any damage or wear and ensure it remains effective over time

8. Daliy Care and Maintenance of Bollard Barrier

In order to increase lifespan, stable performance and reduce repairs, it is essential to keep daily care and maintenance of bollard barrier. Below is a task list

1. Inspect the bollards for any signs of damage, such as cracks or dents.

2. Check the hydraulic fluid levels and top up if necessary, using the recommended fluid type.

3. Check the hydraulic hoses for any signs of leaks or wear and tear, and replace as necessary.

4. Lubricate all moving parts with a suitable lubricant to ensure smooth operation.

5. Clean the bollard barriers with a soft cloth and mild detergent, avoiding abrasive cleaners or solvents that could damage the finish or components.

6. Check the operation of the bollard barrier using the control system, ensuring that they raise and lower smoothly and without any abnormal noises or vibrations.

7. Remove any debris or obstacles that may be obstructing the bollards, such as leaves or small rocks.

8. Ensure that the bollard barriers are free from any moisture or water, especially in colder climates where freezing could damage the hydraulic system.

9. Document any maintenance performed, including fluid top-ups, hose replacement, or any other repairs or adjustments made to the bollard barriers.

By performing these daily care and maintenance tasks, you can help ensure that your bollard barriers operate smoothly and reliably over the long term.

FAQ about Telescopic Bollards (Retractable Bollards)

1. What is the maximum weight capacity of telescopic bollards?

Telescopic bollards have a weight capacity of up to 80 tons or more, which makes them suitable for use in high-security areas such as government buildings, military installations, and airports.

2. How deep do the telescopic bollards need to be installed in the ground?

Generally, the telescopic bollards need to be installed to a depth of 1300mm to 1400mm below the ground level.

3. How long does a telescopic bollard take for the bollards to fully retract and extend?

Telescopic bollards are designed to fully retract or extend within 3-4 seconds.

4. Can telescopic bollards be customized to fit specific requirements?

Yes, telescopic bollards can be customized to fit specific requirements, such as size, color, and operating characteristics.

5. What are the materials of telescopic bollards?

The materials used to create hydraulic retractable bollards typically include high-strength steel and other durable materials. Macrosafe uses 304 stainless steel to produce telescopic bollards as it has excellent ability to withstand impact and resist damage from environmental factors such as weather and moisture.

6. Are there any ongoing maintenance requirements for telescopic bollards?

Yes, regular maintenance and testing are necessary to ensure the proper function of the telescopic bollards. This may include cleaning, lubrication, and replacement of damaged parts.

7. Can telescopic bollards be integrated with other security systems?

Yes, telescopic bollards can be integrated with other security systems, such as surveillance cameras and access control systems, to enhance overall security measures.

8. Are telescopic bollards a reliable security solution?

Yes, telescopic bollards are a reliable security solution as they are designed and manufactured to strict standards, and undergo rigorous testing before installation.

9. What is the lifespan of telescopic bollards?

The lifespan of telescopic bollards varies depending on usage and environmental conditions. A typical lifespan can range from 5 to 15 years.

10. How do telescopic bollards provide access for emergency services?

Telescopic bollards can be lowered remotely by authorized personnel, such as emergency services or security personnel, to allow quick access in the event of an emergency.

11. Can telescopic bollards be used in harsh weather conditions?

Yes, telescopic bollards can be used in harsh weather conditions, as they are designed to withstand extreme temperatures, rain, and snow.

12. Are telescopic bollards environmentally friendly?

Yes, telescopic bollards are environmentally friendly as they are designed to minimize energy consumption, emit no pollution, and do not require oil changes or other maintenance tasks that may harm the environment.

13. Can telescopic bollards be controlled remotely?

Yes, telescopic bollards can be controlled remotely using a variety of different methods, such as a physical key, a remote control, or a signal from an access control system.

14. What is the maximum height of a telescopic bollard?

The maximum height of a telescopic bollard normally is 600mm. It can also be customized according to the requirements of the installation site.

15. How do telescopic bollards compare to other security solutions?

Telescopic bollards provide a higher level of security than traditional barriers, gates, or fences, as they are physical barrier that prevents access to an area.

More Articles:

Road Blockers: The Ultimate Guide to Choosing the Right Solution

How much is a turnstile gate? | Best Buying Guide

Top 5 Tripod Turnstiles in 2024 | Turnstile Buying Guide

Why turnstiles are perfect access control solutions for gyms?

TOP 5 Most Popular Flap Barrier Gates for Entrance Control

Compared with ordinary turnstiles, what are the advantages of glass turnstiles?

What are the types of half-height turnstiles?

Top 9 Benefits of Turnstile Barrier Gate for Your Business

8 Tips For Choosing Best Swing Barriers in 2024

Quick Installation of Speed Gate | 2024 Lastest Guide

Responsive and fast rising & lowering

Responsive and fast rising & lowering Complicated installation and high maintenance costs

Complicated installation and high maintenance costs Excellent waterproof performance, long service life, suitable for harsh environments

Excellent waterproof performance, long service life, suitable for harsh environments A little bit Slower rising & lowering than pneumatic

A little bit Slower rising & lowering than pneumatic Lower cost

Lower cost  Poor waterproof performance, not suitable for rainy environment

Poor waterproof performance, not suitable for rainy environment

Lower cost and simple maintenance

Lower cost and simple maintenance The rise of bollards depends on manpower

The rise of bollards depends on manpower

Lower cost, easy installation

Lower cost, easy installation Not flexible, non-retractable

Not flexible, non-retractable